Pioneering sustainable thinking within optical lighting

We have identified and mapped six areas to minimize our own and the lighting industry’s carbon footprint. Guidance in designing energy-efficient luminaires, a constant hunt for green materials and an inhouse conversion to green energy are some of the initial actions.

In 2020, we at Ingemann Components embarked on a journey to map and identify how we can contribute to reducing the CO2 emissions related to optical lighting solutions.

“Our motivation for working with sustainability was neither pure philanthropy nor calculated business. After looking into lighting from a CO2 reduction perspective we soon realized that we could make a sustainable business model, combining our knowledge on optics and materials, with our in-house measuring facilities as well as our contact with customers and suppliers,” says Dorthe Hillerup Vedsted, Director at Ingemann Components.

In cooperation with the consultancy company Viegand Maagøe, we mapped our direct and indirect impacts on the environment. It quickly became clear that around 75% of the carbon footprint comes from the use phase of the luminaires. An area that we can only affect indirectly, but nonetheless, we have an ambitious goal of reducing the CO2 emission related to the use phase by 80%.

“We intend to reach this goal by supplying CO2 calculation data to our customers to increase awareness of the long-term effects of products. For example, we have developed a CO2 Calculator to help lighting manufacturers make the most sustainable energy and material choices ,” explains Dorthe Hillerup Vedsted.

First step in a sustainability strategy

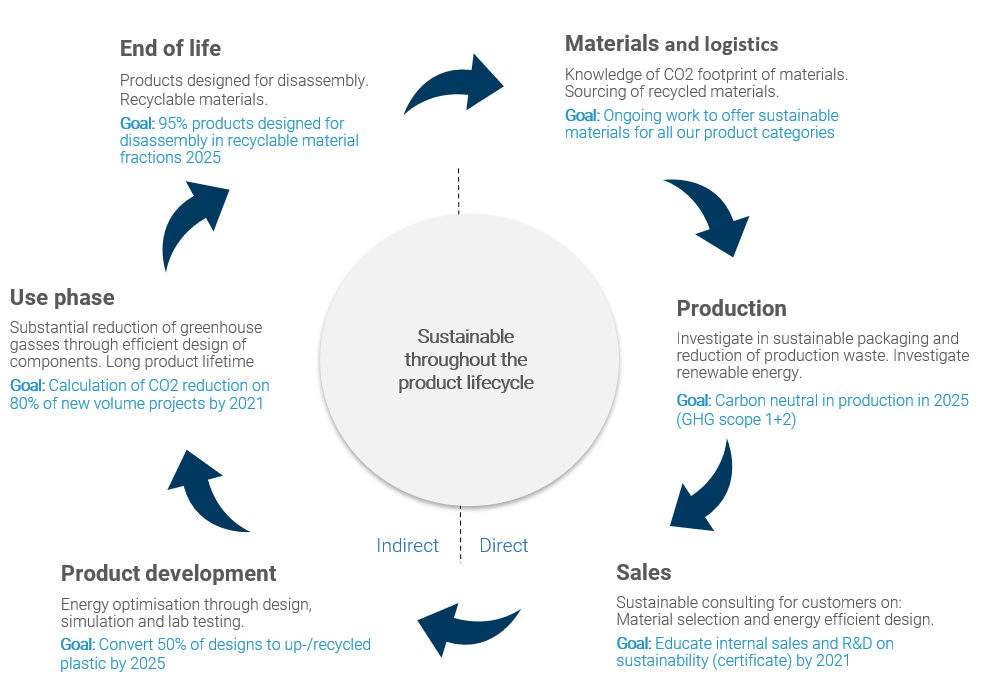

As part of the work with a sustainable approach Ingemann created a strategy that identifies how we can contribute to a CO2 reduction.

From our position in the value chain Ingemann has a number of direct points of influence on CO2 reduction, by focusing on materials, on own production and on sharing our knowledge in the sales and co-development phase with the customer.

However we also aim at pushing sustainable solutions into the part of the product lifecycle that we don’t control directly, such as product development, use phase and end of life.

Ingemann has identified six areas where they have an impact on the CO2 emissions and defined ambitious goals for each area.

We are already advising our customers on how to design the most energy-efficient luminaires by the means of our expert knowledge about optical lighting solutions. Additionally, a new guidance tool for customers on how to develop the most sustainable solutions is in the making.

Ongoing hunt for sustainable materials

A major and direct contributor to our carbon footprint is the materials used for components, where we experience an increasing interest in green materials among lighting manufacturers.

“We are constantly on the outlook for green materials that can either replace or complement our product portfolio. But the maturity level for green materials among our suppliers is very different depending on geography,” tells Dorthe Hillerup Vedsted.

In general, she experiences that European suppliers are very focused on sustainable materials whereas Asian suppliers are lagging behind.

Re-/upcycling of used luminaires is another activity that we are investigating; thus, we have recently entered into a cooperation with THE UPCYCL who upcycles waste materials to new products.

Mapping of own CO2 emissions

Our own carbon footprint is limited to electricity, heating and supplies for running an administration. The water consumption is limited and not related to the production. Therefore, our main focus is currently on phasing out the use of fossil fuels and convert to green power.

“We are investigating the possibility of introducing heat pumps and convert to green power in our facility. Heat pumps are to a large extend wind driven,” tells Dorthe Hillerup Vedsted who expects to finalize this project in autumn 2021.

The implementation of our sustainability strategy is an on-going and long-term project, but along the way we will share smaller and larger gains, so more to come.

For more information, please contact

Director, Lars Saquero Møller

E-mail: lsm@ingemanncomponents.com