How to design for later recycling

We have gathered 8 pieces of advice to keep in mind when you design a luminaire bound for recycling at a later stage in the product life cycle.

As a rule of thumb, a luminaire has a lifespan of 20 years, but this is only first stage in a fast-turning product life cycle. An increased focus on sustainable manufacturing within the lighting industry implies that later re- or upcycling of the luminaire should be considered and included in the design phase of the product.

For luminaires, this can be done by using easy-to-change light sources, and optical lighting components and batteries that are replaceable.

What to consider

When you design a luminaire bound for later disassembly, it’s not only paramount to consider how the different parts are assembled, but also to verify whether the chosen combination of plastics can be recycled at a later stage without further disassembly.

8 PIECES OF ADVICE

- Choose compatible and recycled materials.

- Avoid (or limit) using materials that require separation before recycling.

- Use as few components and component fractions as possible.

- Standardize the use of fasteners, use commonly available parts, and maintain design consistency.

- Make non-compatible components easily separable.

- Apply non-contaminating markings to materials for ease of sorting.

- Maintain good access to components and fasteners.

- Don’t paint plastic parts to avoid contaminating other plastics when recycled.

Compatibility of plastics

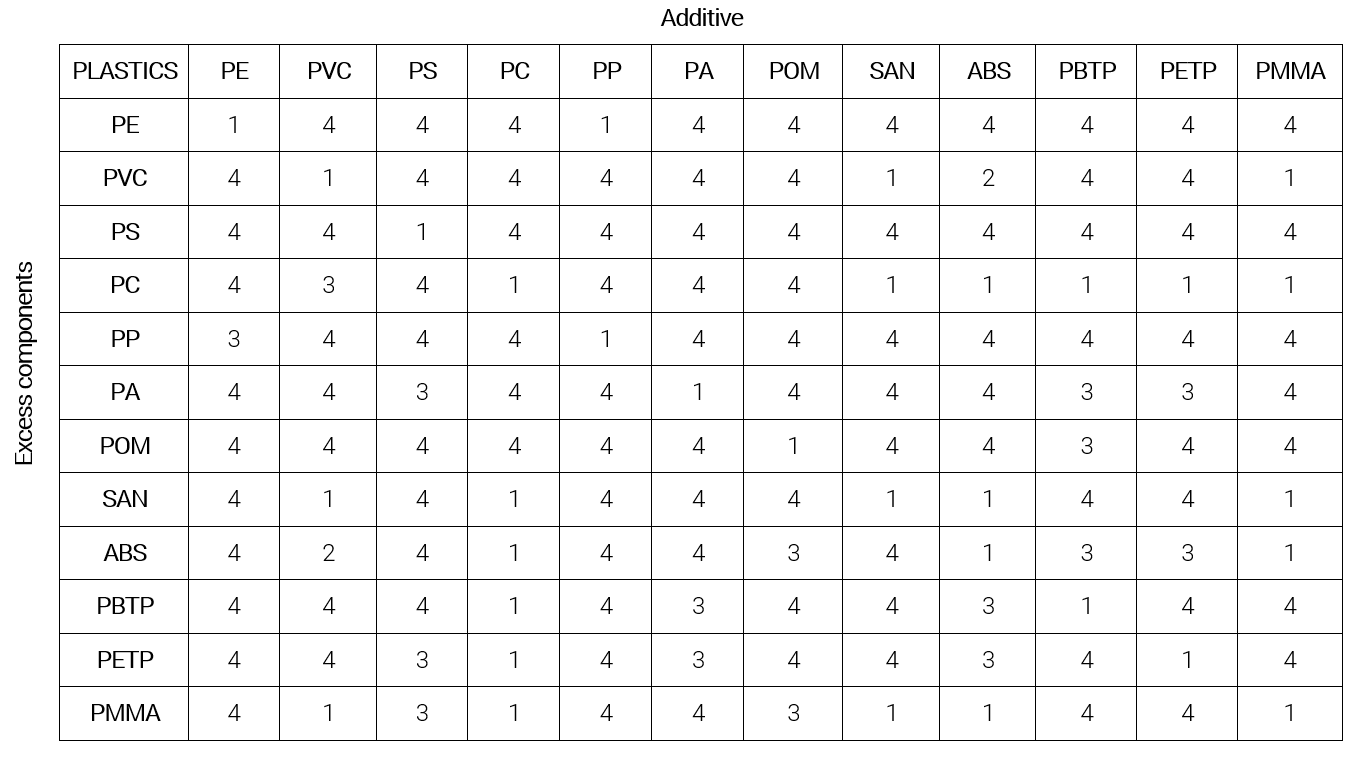

In the chart below, the recycling compatibility of different types of plastics is presented.

1= Compatible, 2 = Compatible with limitations, 3 = Compatible only in small amounts and 4 = Not compatible.

How to read the chart

- ‘1’ indicates that the two types of plastics are compatible and don’t require disassembling before recycling.

- ‘4’ indicates that the two types of plastics need to be disassembled before recycling.

As an example, this means that PE + PP are compatible. On the contrary, PE + PVC are non-compatible and an alternative combination should be considered.

Sustainability at Ingemann Components

As a part of Ingemann Components’ Sustainability Strategy, we are looking into both recycling and upcycling.

“In 2025, we have the goal that 95% of our solutions should be designed for disassembly in recycled materials fractions. Not only, does it allow you to retain value, but it’s also a way to ensure a meaningful next life of the materials. We see this as good sustainable thinking,” says Dorthe Hillerup Vedsted, Director at Ingemann Components.

We hope you find this information beneficial. If you have any questions or need our support, please contact us at sales@ingemanncomponents.com.

[i]The compability chart is based on: Chiodo, J., 2005. Design for Disassembly Guidelines. Available at:

http://www.activedisassembly.com/strategy/design-for-disassembly/.